Welcome To Technimark

Longford, Ireland

Crafting The Future Of Healthcare

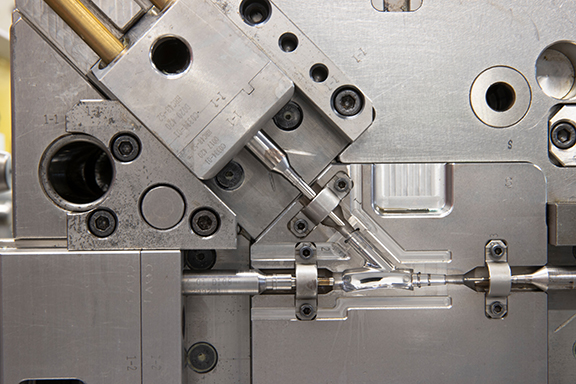

Technimark Ireland is a MedAccred certified medical production facility creating products to support our medical customers around the globe. This facility is an essential part of the Technimark global network providing premier, precision injection-molding, complex automated assembly and exceptional customer experience.

Like all our facilities, we operate an active, fast-paced atmosphere that encourages teamwork, innovative thinking and mutual respect.

About Longford

Longford lies at the heart of Ireland and is steeped in ancient Irish mythology and lore. From the reedy shores of Lough Gowna to the banks of the River Shannon, the quiet countryside of County Longford overflows with rural charm. A low-lying, inland county, it’s an outdoor enthusiast’s dreamland. Longford boasts a vibrant collection of communities with a rich historical background. The County has plenty to offer in sport, culture, literature, amenities, festivals, events, retail, and dining.